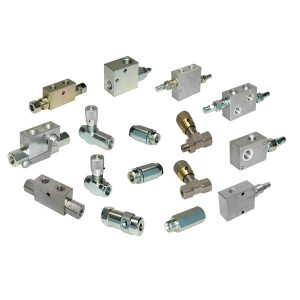

Hydraulic valves

High-Quality Hydraulic Valve for Safe and Reliable Operation

Specialized valves are required to safely and reliably control hydraulic circuits in industrial plants. A pressure relief valve in hydraulic systems must endure significant stress consistently. To accommodate the needs of each plant, various valve designs have been established. These include check valves, as well as directional and control valves. Depending on the chosen design, one can opt for either mechanical or electromagnetic configurations.

Features and Characteristics of an Electromagnetic Directional Valve

An exceptional variant of the hydraulic valve is the electromagnetic directional valve. This valve is utilized, for instance, in controlling hydraulic cylinders. The force transmitted through the hydraulic oil also moves the valve in the desired manner. The directional valve is primarily responsible for controlling the various paths the oil traverses within the hydraulic system. Through a joystick, precise control over this hydraulic valve can be achieved. The advantage of electromagnetic valves lies in their particularly sensitive control.

Forestry Relies on the Use of Specialized Hydraulic Valves

In forestry, particularly in wood splitters operating at up to 160 liters/min, a specialized valve is employed. This valve is known as the rapid advance valve, specifically developed for this application. Through the utilization of this component, a significant time-saving in wood harvesting is achievable, enhancing work efficiency. Additionally, employees benefit from noticeable ease in their tasks. The wood splitter can be operated at two speeds with the use of this hydraulic valve. With high flow rates, an increase in splitting speed is possible, substantially reducing the time required for this task.