SAE flange fittings 6000 PSI everything you need to know

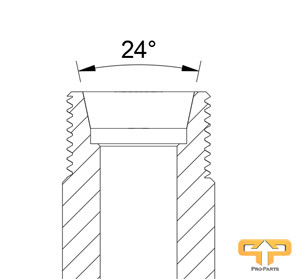

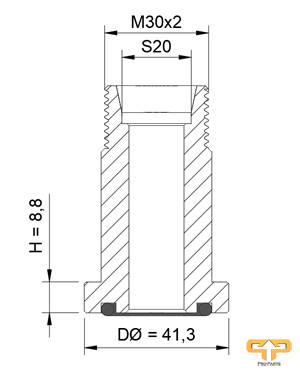

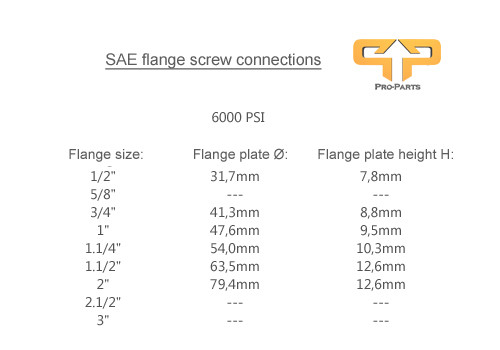

SAE flange fittings are renowned for their high strength and reliability, providing a robust and secure connection in applications with high-pressure requirements. Metric heavy and light SAE flange fittings are specifically designed for applications with varying diameters and heights to ensure a perfect fit and a secure connection.

Metric heavy flange fittings, due to their larger flange plate, are particularly robust and can easily withstand high-pressure requirements. With their special seals and reinforcements, they offer a secure and reliable connection that meets the demands of challenging applications.

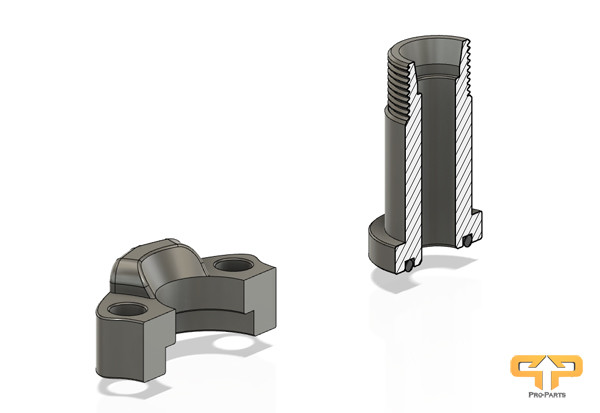

When assembling SAE flange fittings, it is important to note that flange halves are required to securely mount the flange fittings. In this process, the flange plate is brought into contact with the sealing surface of the hydraulic cylinder or pump, thereby firmly pressing the O-ring in the groove of the flange plate against the sealing surface. To ensure an optimal seal, it is important to tighten the flange halves with a specific preload pressure.

When tightening the flange halves, a certain force is applied to the flange plate, pressing the O-ring against the sealing surface of the hydraulic cylinder or pump. This creates a preload pressure on the O-ring, preventing hydraulic fluid leakage. Therefore, it is important during the assembly of SAE flange fittings to ensure proper installation and adherence to the preload pressure to guarantee the proper functioning of the hydraulic system.

Regardless of the choice between metric heavy or light flange fittings, SAE flange fittings are an excellent choice for a wide range of applications in hydraulic systems. With their high performance and reliability, you can rely on them to provide a secure and dependable connection even in demanding applications.